These days, Technology is advancing at a very fast pace. This meteoric shift brings us exciting new tools and concepts that support a variety of sectors. AI vision seam tracking sensors are one reason advanced machine vision is quickly becoming a game changer for welding. These special sensors are also helping improve welding by monitoring the seams where the metal pieces are merged together. Why this matters: Good welding is crucial to strong and safe products.

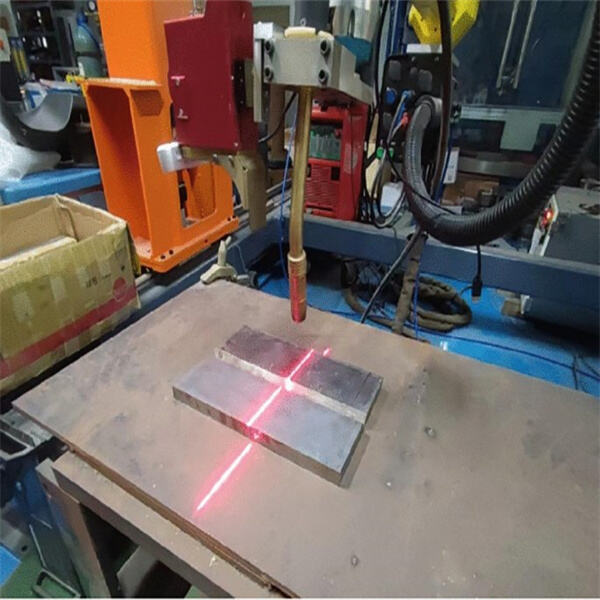

MINYUE AI vision seam tracking sensors as well as laser seam tracking sensor adopts specialized smart technology to accurately follow the seams and weld of two pieces of metal joints. This ensures that welders can make smooth and quality welds without much effort. The sensors are quite sophisticated and can observe the workpiece as it is being processed. This allows them to observe what is happening in real-time, ensuring that the welding is performed as precisely as possible. With this kind of assistance, welders can have excellent results every time they weld.

MINYUE's intelligent vision sensors utilize the power of AI technology to achieve more accurate and efficient welding process. These sensors can identify even minute issues with the welds so that welders can address them immediately, before they become big problems. The speed of this response improves the welds' final quality. Further, the sensors can assist in automating some aspects of the welding process, allowing for faster task completion with less probability of error. This allows welders to accomplish more in less time, and makes them better performance to carry out their work.

With MINYUE smart seam tracking sensors and line tracking sensor, factories now can achieve the very level of precision and accuracy that had always been very difficult. The sensors can lead real-time performance tracking of seams without breaking, thus achieving uninterrupted, continuous, smooth, and rapid welding without stopping. This allows them to develop the peace of mind knowing that they will be getting the highest quality product possible. These sensors have enabled processes in factories to be faster, more efficient, and easier to manage overall.

Artificial intelligence vision has upgraded welding quality and speed of work. “MINYUE’s tracking sensor are able to detect any potential issues as they are forming, giving the welders an opportunity to fix the problem before the issue becomes too serious,” This leads to quality welds, reducing the need to redo work later. In addition, the sensors will help welders by automating certain tasks. This automation allows welders to devote more time to other critical aspects of their job. Essentially, this creates a combination of quality being higher while speed is also increasing, and this means businesses are starting to see much bigger improvements in their welding processes, which is crucial to their success.

AI vision seam tracking sensors as well as automatic weld tracking sensor are designed specifically for welders to give great and precise results. These sensors can detect seams with astonishing accuracy, and ensure that every weld they generate is high-quality. They use AI technology to analyze this data instantly and adjust accordingly for optimal performance. These sensors can allow the welder to produce high quality welds all the time since they can monitor the process in real-time to make adjustments, as a result the welder will perform better and customer will be happy with the results.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.